e-Mail: contact@zena.net

|

|

|

|||

|

|

|

A Typical ZENA™ Model UB2 Universal Bracket Kit Automotive Welder Installation

|

e-Mail: contact@zena.net |

A Typical ZENA™ Model UB2 Universal Bracket Kit Automotive Welder Installation |

|||||||||||

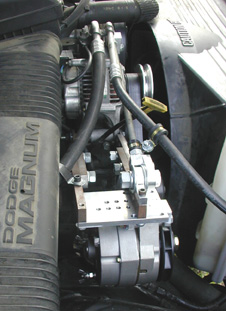

A V-8 Dodge truck with a ZENA mobile welding system

| In this application, a V-8 Dodge truck, the vehicle owner installed a MW150KB welding system. He determined that the best fit for the ZENA power generator, in his truck, would be obtained by using the ZENA UB2 universal power generator mounting bracket so as to mount the power generator UNDER the UB2 frame members using the A300A bracket supplied as part of his MW150KB truck kit. |

|

|

|

In this fairly typical piggy-back installation,

V-belt drive for the power generator is obtained by using a standard model AAPK Add-A-Pulley

alternator power take off kit (also part of the MW150KB). Belt tensioning by means of an idler pulley was determined to be best. The choice of mounting position for the generator facilitates the use of the idler pulley (supplied with the UB2) on the inbound (slack) side of the power generator's drive pulley. This insures excellent belt wrap around the power generator pulley and, as mentioned before, provides a means of tensioning the drive V-belt. |

|

UB2

bracketing in place, pulley |

| Since, in this application, the generator

does not have to be moved for belt tensioning, only a minimum of extra space is required

around the generator -- making it easier to fit the unit to this particular vehicle.

Because the generator does not have to be moved for belt tightening, other than providing some strain relief points to hold hoses out of the way, no extra modification to hoses or hose routing was required. |

|

| UB2 bracketing in place, power generator mounted |

|

|

The photos of this installation show the power generator in place on the UB2, illustrate the positioning of the idler pulley and hoses, and show the final belt path from the Add-A-Pulley to the welding power generator. |

|

Close-up view of UB2 vertical support / tensioning / idler pulley bracket component |

|

These photos also show the use of “all-thread” rod (supplied with the UB2) in conjunction with the “standard” UB2 bracing/stiffening/support components which are designed to be used with this type of threaded rod. In this case, these support components are attached to the third mounting bolt on the stock alternator bracketing. The customer did, however, require a longer piece of all-thread than the 1’ length which was supplied with the UB2.

|

|

|

UB2 bracketing

and power generator in place. |

|

The welding control module was mounted

remote from the generator in this application. Welding cable hookup is by means of the BJ150.4 quick disconnect kit supplied as part of the MW150KB. In this application, thanks to the versatility of the UB2, no welding or extra bracketing components had to be fabricated! A ZENA ASC1 automatic speed control was used to directly control the vehicle's throttle pedal mechanism  |

|

UB2

bracketing and power generator in place, |

|

|

Time to install -- approximately 2 hours. |

|

|

US & Foreign Patents Pending © Copyright 2004 by ZENA, Incorporated. All rights reserved. [an error occurred while processing this directive] |