|

We have just what you

need to use your constant

current

underhood or free standing engine driven ZENA welding power generator as a power

supply for:

- your existing constant

voltage/constant current compatible

MIG

suitcase type spool feeder/torch,

OR

- your existing MIG spool gun, OR

- for DC TIG welding,

with your existing TIG

torch.

|

|

Use a Spool Gun or Spool Feeder

with your welder

|

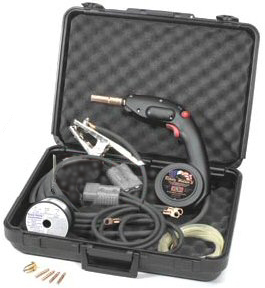

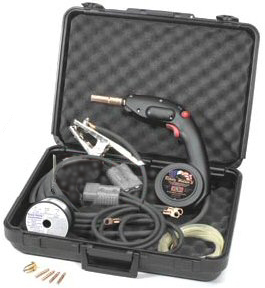

If you don't already

have a portable MIG setup, we stock a special configuration Ready Welder

spool gun which we factory equip with a special ZENA spool gun adapter. Because

it's perfectly matched with a special version of our ZENA spool gun power supply,

this portable MIG spool gun (our part # ZRW10000,CS) is lighter and more compact

than other Ready Welder units. It's also less expensive than buying each item separately.

Priced below the costs of either item purchased separately, if you don't already

have a spool gun, this is the way to go!

Adapters

for many popular models of MIG and TIG torches are available

FOR EXAMPLE:

If you

have a constant voltage Spool Feeder or Spool Gun

Two different adapters are available

for constant voltage spool feeders and spool guns (including the popular Ready

Welder MIG spool gun). These adapters include an isolated solid state regulated DC

to DC power converter which serves to provide voltage for the spool feeder's (or

the spool gun's) wire feed motor. When the adapter is installed, the wire feed switch

on the MIG torch (or a separate power button attached to the torch handle) controls

welding power On/Off function as well as wire feed On/Off function. A power

control dial which controls welding power (amperage) is attached to the spool feeder

case or, in the case of a spool gun adapter, the dial is built into the adapter/power

supply module itself.

In addition to now being able to

operate your spool feeder any where you can take your ZENA welder, you now have instant

power control and, thanks to the fingertip power On/Off control, a much safer welder.

The adapters also provide electrical switching contacts to control gas valves and

other related functions.

If you

have a constant current compatible Spool Feeder or Spool Gun

Two different adapters are available.

When the adapter is installed, the wire feed switch on the MIG torch (or a separate

power button attached to the torch handle) controls welding power On/Off function

as well as wire feed On/Off function. A power control dial which controls

welding power (amperage) is attached to the spool feeder case or, in the case of

a spool gun adapter, the dial is built into the adapter/power supply module itself.

In addition to now being able to

operate your spool feeder any where you can take your ZENA welder, you now have instant

power control and, thanks to the fingertip power On/Off control, a much safer welder.

The adapters also provide electrical switching contacts to control gas valves and

other related functions.

If TIG

is what you need

Again, two different adapters are

available. Both provide On/Off control by means of a foot switch. In one a dial is

provided for power control and in the other the power control function is built in

to the foot switch assembly -- creating a complete foot operated welding control

assembly.

If desired, a torch mountable push

button may be substituted for the foot switch (On/Off) power control.

Note that the ZENA mobile welding

systems TIG interface does not include a sparking system to facilitate TIG arc starting

and that your TIG arc must be started by scratching. Normal care not to stick the

TIG electrode to the material and contaminate your weld joint is required.

Note, also, that the output of the

ZENA power generator is DC, not AC, so AC TIG welding is not possible -- only DC

TIG. DC TIG welding is not recommended for welding thin aluminum. DC is perfect for

TIG welding other materials. But, going strictly "by the book", AC should

be used for TIG welding aluminum, not DC. With this said, we have had customers report

that they have achieved good results welding aluminum, however, we can not guarantee

that this will hold for all cases.

Variations

on the MIG or TIG controls can also be used for stick welding

Frequently used in

man lifts, our power control interfaces can be used to provide, for example, foot

switch control of power generation and/or panel mounted power control dials -- making

it possible to use "standard" electrode holders instead of ZENA's combination

electrode holder/welding control. If you application needs a special user interface,

just call us -- it's quite possible that we have just what you need "on the

shelf".

Just

like the other ZENA welding system components, our interface adapters are built for

heavy duty commercial use

Your MIG or TIG adapter will carry

our standard three

(3) year limited warranty

which does not exclude commercial or marine use. Built to meet or exceed

military and underground mining equipment specifications, no other line of welding

products better meets the needs of people who need access to superior, high-power

welding equipment that can operate reliably and safely in remote locations.

Buy

risk free using

our Secure

Online Store.

NOTE:

Constant

Current / Constant Voltage?

These are terms which refer to the type of welding current produced by a given welder.

In most cases, stick, TIG, and high end MIG welders are constant current. Constant

voltage current is usually used in MIG welders where the welding current is also

used to power the wire feed motor (which would otherwise be damaged by the higher

voltages found in constant current welders).

Duty

cycle

is the welder specification which defines the number of minutes, within a 10 minute

period, during which a given welder can safely produce a particular welding current.

(For example, with a 30% duty cycle welder, you have to wait 7 minutes for every

3 minutes of welding.) |

ZENA™ is

a trademark owned by ZENA, Inc. for its welding systems and related products.

US &

Foreign Patents Pending

© Copyright

2001, 2002, 2003 by ZENA, Incorporated. All rights reserved.

NOTE: These

adapters work with MIG, FCAW, and TIG equipment designed to work with engine driven

welders made by Miller, Lincoln, Hobart, Century, Esab, HTP, Mitsubishi, Thermal

Arc, Tweco, Forney, Mobi Weld, Premier Power, Mobi Arc, and other companies. When

comparing specifications, you will find that our 150A welding power generator is

comparable to, and will do the same job as, for example, a Miller 225 Bobcat welder,

a Hobart 250A welder, a Century 200A welder, or a Lincoln Ranger 8 welder. Of course,

160A, 175A, 180A, 275A, or even 300A, or 400A welders would be also in the same category.

NOTE2:

These adapters are perfect for service trucks (particularly popular are Ford Chevrolet

and Dodge Diesels) and all types of 4x4's (including Jeep, International, and Toyota),

this welder can also be installed on all types of heavy equipment, including backhoes,

front end loaders, track loaders, forklifts, and tractors as well as all types of

utility vehicle.

[an error occurred while processing this directive]

|