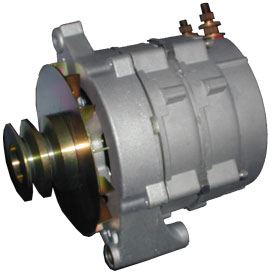

NO, it's NOT an automotive alternator.

NO, it's NOT an automotive alternator.

Use "back" arrow on browser to return to previous screen. |

|

Back to Alternator FAQ Index |

|

To ZENA Web Site Map |

NO, it's NOT an automotive alternator.

NO, it's NOT an automotive alternator.

Its internal functioning, design, and construction is much more similar to other high-end welding power generators -- but more compact, thanks to our advanced technology

To keep costs low and to make installation easier, we do use automotive alternator cases for the front portion of our Welding Power Generators. However, the internal components are not standard automotive components. Far from it! In fact, that's why we often refer to it as a welding power generator rather than an alternator. To name just a few of many performance and/or reliability features:

We use special hand-wound rotors and stators. Made to our own specification they

contain so much additional copper and iron that it's easy to feel the substantial

difference in weight between our power generator and a "standard" automotive

alternator which is similar in size.

We custom build our own high-power bridge rectifier assemblies. (The rectifiers in our 150 amp. welding power generator can handle over 300 amps. -- and our 200 amp. model can handle over 500 amps.)

Our 5/16" output connection terminals (in all models) are just what they appear to be -- and more. Specially fabricated in our machine shop, they are highly conductive 5/16" bolts with very large internal contact surface areas capable of transmitting sustained currents of more than 500A without failure. They are not small diameter (1/4" or less) machine screws or bolts equipped (cosmetically) with large visible end studs.

All electrical components are electrically isolated from the case.

Special provisions for extra cooling are made.

All controls are proprietary (patents pending) designs.

All moving parts (bearings, brushes, etc.) are the heaviest duty components available.